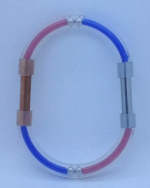

im thinking I was just scammed out of 100 $. my "ring of power has no voltage. with readings of .00000 voltz I am convinced this is a big scam. do not buy!!!!!

ring of power no voltage

- Thread starter thechocolate

- Start date

- No one is chatting at the moment.

-

MoS Notifier:

POGLOL is our newest member. Welcome!

MoS Notifier:

POGLOL is our newest member. Welcome! -

MoS Notifier:

HungryWetThroat is our newest member. Welcome!

MoS Notifier:

HungryWetThroat is our newest member. Welcome! -

MoS Notifier:

bobardon974 is our newest member. Welcome!

MoS Notifier:

bobardon974 is our newest member. Welcome! -

MoS Notifier:

Longrunner is our newest member. Welcome!

MoS Notifier:

Longrunner is our newest member. Welcome! -

MoS Notifier:

Jaime_ma_bite is our newest member. Welcome!

MoS Notifier:

Jaime_ma_bite is our newest member. Welcome! -

MoS Notifier:

Alex7x6 is our newest member. Welcome!

MoS Notifier:

Alex7x6 is our newest member. Welcome! -

MoS Notifier:

2345899024 is our newest member. Welcome!

MoS Notifier:

2345899024 is our newest member. Welcome! -

MoS Notifier:

weird_al_yankadick is our newest member. Welcome!

MoS Notifier:

weird_al_yankadick is our newest member. Welcome! -

MoS Notifier:

puporis is our newest member. Welcome!

MoS Notifier:

puporis is our newest member. Welcome! -

MoS Notifier:

hungSoIo is our newest member. Welcome!

MoS Notifier:

hungSoIo is our newest member. Welcome! -

MoS Notifier:

dixiecup is our newest member. Welcome!

MoS Notifier:

dixiecup is our newest member. Welcome! -

MoS Notifier:

Freddyjack is our newest member. Welcome!

MoS Notifier:

Freddyjack is our newest member. Welcome! -

MoS Notifier:

Yerba is our newest member. Welcome!

MoS Notifier:

Yerba is our newest member. Welcome! -

MoS Notifier:

asianj is our newest member. Welcome!

MoS Notifier:

asianj is our newest member. Welcome! -

MoS Notifier:

MrJerkOff is our newest member. Welcome!

MoS Notifier:

MrJerkOff is our newest member. Welcome! -

MoS Notifier:

Lapadjhapad is our newest member. Welcome!

MoS Notifier:

Lapadjhapad is our newest member. Welcome! -

MoS Notifier:

SELSFY is our newest member. Welcome!

MoS Notifier:

SELSFY is our newest member. Welcome! -

MoS Notifier:

dsfbasyudgfa54 is our newest member. Welcome!

MoS Notifier:

dsfbasyudgfa54 is our newest member. Welcome! -

MoS Notifier:

Moha_91 is our newest member. Welcome!

MoS Notifier:

Moha_91 is our newest member. Welcome! -

MoS Notifier:

ordnell is our newest member. Welcome!

MoS Notifier:

ordnell is our newest member. Welcome! -

MoS Notifier:

digital_banana is our newest member. Welcome!

MoS Notifier:

digital_banana is our newest member. Welcome! -

MoS Notifier:

Slimbo Jimbo is our newest member. Welcome!

MoS Notifier:

Slimbo Jimbo is our newest member. Welcome! -

MoS Notifier:

SirPipe is our newest member. Welcome!

MoS Notifier:

SirPipe is our newest member. Welcome! -

MoS Notifier:

notapagan is our newest member. Welcome!

MoS Notifier:

notapagan is our newest member. Welcome! -

MoS Notifier:

Juiceman79 is our newest member. Welcome!

MoS Notifier:

Juiceman79 is our newest member. Welcome!